Are Tesla Batteries Recyclable

As the automotive industry shifts towards sustainable energy solutions, electric vehicles (EVs) are becoming increasingly popular. Leading this revolution is Tesla, which has set itself apart not only through innovative vehicle design but also through a commitment to sustainability and environmental conservation. Central to this commitment is Tesla battery recycling, a crucial process that ensures the responsible disposal and recovery of valuable materials from used batteries. This article explores the intricacies of Tesla’s recycling process, addressing questions like “Are Tesla batteries recyclable?” and highlighting the importance of this practice in today’s world.

Understanding the Importance of Battery Recycling

The demand for electric vehicles has surged in recent years. According to industry analysts, lithium-ion battery production has increased over tenfold to meet this rising demand. This spike in battery use has led to a looming challenge: what happens to these batteries once they reach the end of their life cycle? It’s estimated that by 2030, the world will generate over two million metric tons of spent lithium-ion batteries annually. Therefore, effective recycling processes are essential to meet this challenge and reclaim valuable materials within these batteries.

Battery recycling serves several purposes:

Environmental Conservation: When batteries are improperly disposed of, they can harm the environment. Landfilling them can result in soil and water contamination. Conversely, recycling allows for the safe recovery of precious materials while minimizing waste.

Resource Efficiency: Extracting the raw materials for battery production is energy-intensive and often harmful to the environment. By recycling batteries, manufacturers can recover materials like lithium, nickel, cobalt, and aluminum, significantly reducing the need for new mining operations.

Cost Savings: As demand for electric vehicles continues to rise, the cost of raw materials can increase. By recycling old batteries, companies like Tesla can benefit from lower production costs associated with sourcing recycled materials.

What Materials Are Found in Tesla Batteries?

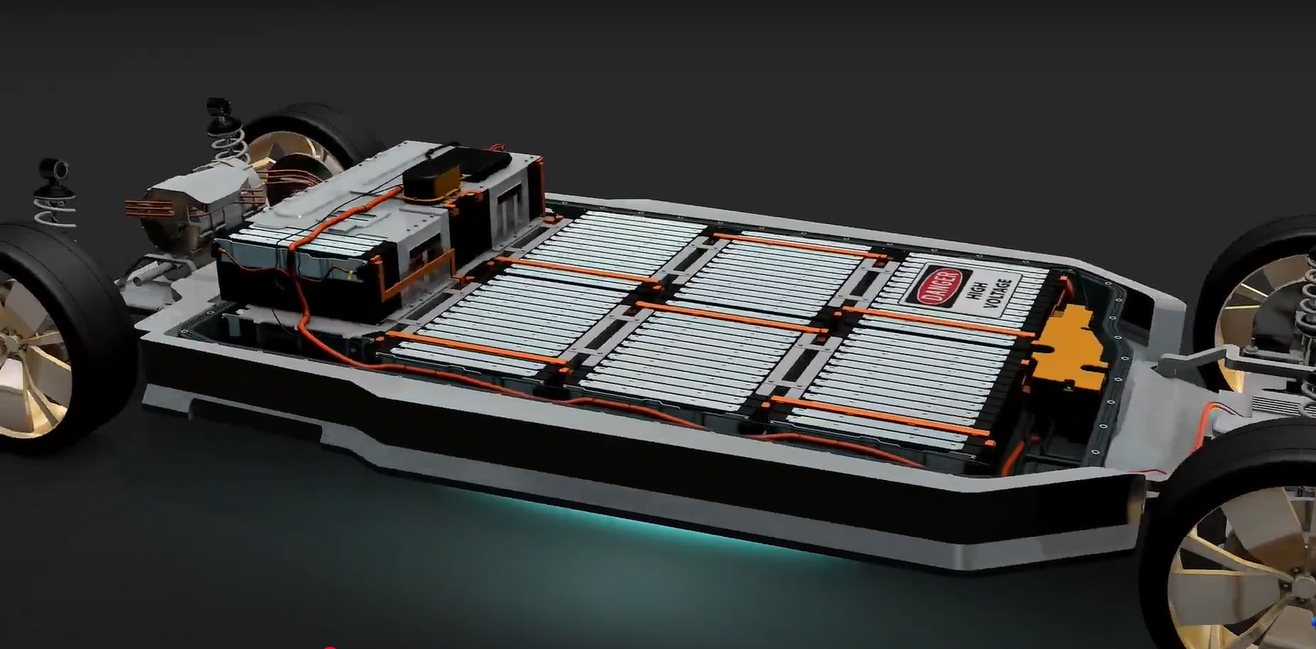

To fully grasp the significance of Tesla battery recycling, it is vital to understand the composition of Tesla’s batteries. Tesla lithium-ion batteries primarily consist of:

- Lithium Metal Oxides: These materials, including cobalt and nickel, are essential for battery performance.

- Graphite: Used in the anode, this material plays a crucial role in the battery’s capacity to store energy.

- Lithium Salts: These are found in the electrolyte, facilitating ion movement between the battery’s electrodes.

Importantly, Tesla batteries do not contain hazardous substances like lead, mercury, or cadmium, making the recycling process safer and more manageable.

The Tesla Recycling Process

Extending Battery Life Before Recycling

Before recycling old batteries, Tesla employs strategies to extend their lifespan. Once a battery can no longer power a Tesla vehicle, it doesn’t necessarily mean it is completely dead. These batteries can still be repurposed for other uses, primarily energy storage solutions. For instance, they can support the grid, especially alongside renewable energy sources like solar and wind, providing energy storage when supply is inconsistent.

The Recycling Facility

In 2019, Tesla announced the establishment of its own recycling facility, emphasizing its commitment to a closed-loop recycling system. This facility partners with third-party recyclers worldwide to ensure efficient and eco-friendly processes. For instance, in Europe, Tesla collaborates with Umicore, a mining company that has adopted a closed-loop strategy, allowing for the recycled materials to be used in their original applications.

The Dismantling Process

When a battery reaches the end of its life and is sent to a recycling facility, Tesla follows a meticulous dismantling process. This process includes the following steps:

Testing Electronics: The first step involves removing all electronic components from the battery cells. Any functioning electronics are reused, while non-reusable parts are sent to recycling facilities for further processing.

Freezing Lithium Modules: After removing the metals and electronics, the lithium modules are frozen using liquid nitrogen. This step makes them chemically inert, which is vital for safe shredding and processing.

Shredding and Separation: The frozen lithium modules are then shredded into tiny pieces. These materials are screened and separated into various components, such as cobalt, copper, and other materials, which can be sold to recycling centers.

Final Processing: The separate components undergo further refining and processing to reclaim valuable materials like nickel, cobalt, aluminum, and copper, which can be reused in new battery production.

Waste Management

Through this comprehensive recycling process, Tesla has achieved impressive results. Approximately 60 percent of the components from end-of-life lithium-ion batteries are recycled, while about 10 percent of battery cases and some electronic components are reused. The only material that typically ends up in a landfill is the harmless fluff, which has been rendered inert during the recycling process.

Economic Aspects of Battery Recycling

Cost is a significant consideration when it comes to battery recycling. Tesla’s partner, Toxco, charges around $4.50 per pound of materials processed. However, due to the increasing demand for electric vehicles and recycled components, recycling fees have decreased by 24 percent, making it more economical for Tesla to recycle batteries rather than relying solely on newly mined materials.

Incentive Programs for Customers

In an effort to enhance the recycling ecosystem, Tesla is also considering implementing an incentive program. This initiative would allow Tesla owners to return old battery modules at battery-swapping stations, providing them with a new battery at a reduced price. Such programs are crucial for educating consumers on battery recycling and ensuring they actively participate in the process.

Industry Comparisons: Tesla vs. Other Automakers

While Tesla is a frontrunner in battery recycling, other automakers are exploring alternative uses for old battery modules. Companies like Hyundai, BMW, and Renault are repurposing old battery packs for energy storage systems rather than recycling them for new materials. Nissan, for instance, uses its old Leaf batteries in automated guided vehicles to enhance efficiency in its factories.

Volkswagen has recently announced plans to open its first recycling plant in Salzgitter, Germany, capable of recycling up to 3,600 battery systems per year in the pilot phase. Although various manufacturers are making strides, Tesla remains unique in effectively recycling its old batteries.

Looking Forward: The Future of Tesla Battery Recycling

Despite the current limitations in battery recycling, the future looks promising. As technology advances and public awareness of sustainable practices increases, the efficiency and effectiveness of Tesla battery recycling processes will likely improve. By prioritizing recycling and circular economy models, Tesla is not only reducing waste but also setting a standard for the entire automotive industry.

Governments and organizations also play a critical role in promoting battery recycling through legislation and incentives. Encouraging responsible disposal and recycling efforts is essential to creating a sustainable future for electric vehicles.

Conclusion

In conclusion, Tesla battery recycling is a critical component in the journey toward sustainable energy and responsible automotive practices. Understanding the composition, recycling processes, and economic implications surrounding these batteries gives us a broader perspective on their lifecycle. As we navigate through an era of electric vehicles, it is crucial to ask, “Are Tesla batteries recyclable?” The answer is a resounding yes, but it is evident that ongoing innovation and collaboration are necessary to address the challenges posed by the growing number of spent batteries.

Tesla’s commitment to sustainability and environmental conservation sets a benchmark for the entire automotive industry. As you consider the future of electric vehicles, remember the integral role that recycling plays in ensuring a greener planet. Whether through Tesla’s strategic recycling practices or the efforts of other automakers, the focus on responsible battery disposal will help shape a more sustainable automotive landscape for years to come.

If you have thoughts or questions regarding Tesla’s recycling practices or the future of electric vehicle sustainability, feel free to share! Let’s keep the conversation going about how we can all contribute to a greener future.